Flexible packaging is usually made from high-quality plastic films made of PET, PE or PP. However, aluminium and paper materials are also being used more and more frequently. When selecting the right packaging material, there are various factors to consider. In order to preserve the aroma and taste of food or to keep pharmaceutical and chemical products sterile and protected, various functional barriers such as SiOX, aluminium or EVOH are also used in the material composites.

To determine the right combination of materials, the following points should be considered:

- Product protection – Depending on the contents, ensure that there is a functional barrier to protect the product.

- Marketing – Special metallic effects or a viewing window can be convincing at the point of sale and strengthen brand presence.

- Sustainability – Recyclable mono-plastic or plastic-free barrier paper protects the environment and supports a sustainable circular economy.

- Processing – It is important that the material works smoothly with the filling and sealing technology used (hot, ultrasonic or cold sealable) to ensure efficient processing.

Common materials for flexible packaging

As described, plastic films and film composites are mainly used. Our selection of flexible packaging materials includes a wide range of different film composites, paper-film composites and plastic-free barrier papers. Our materials are available in various film thicknesses for all applications and also have a functional barrier against oxygen and water vapour penetration. Individual materials also offer additional protection against UV radiation.

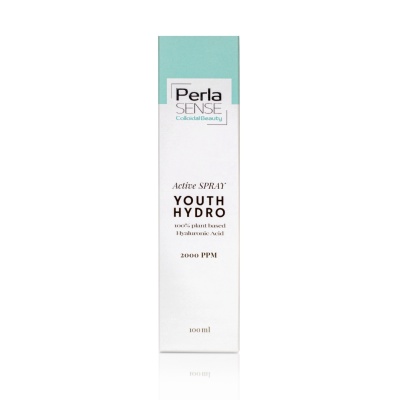

Folding boxes

Folding boxes

Stand-up pouch

Stand-up pouch

.png) Roll labels

Roll labels

Paper cans

Paper cans  Sample boxes

Sample boxes