Flexible packaging consists of high-quality packaging solutions made of plastic, aluminium, cellulose or even paper and is mainly used in the food, chemical and cosmetics industries. Flexible packaging is used for both primary and secondary packaging. If required, it offers long-lasting protection against the penetration of oxygen and water vapour, as well as against aroma loss, mineral oils and UV radiation, thanks to functional barriers.

Areas of application for flexible packaging

Flexible packaging is available in a variety of designs and meets different requirements depending on the industry and contents. Flexible packaging fulfils various functions in the food industry, for example: it protects the product and also serves as a marketing tool. In addition, some types of packaging offer practical additional functions such as pour spouts, tear notches, resealable press closures or aroma valves. Flexible packaging is available in many designs, such as:

- Stand up pouches/Doypacks – for a secure stand on the shelf.

- Flachbeutel/Siegelrandbeutel - für platzsparendes Verpacken.

- Flat Pouches/sealed-edge bags – for space-saving packaging.

- Sealing lids / sealing plates – for sealing cups and tins.

- Sachets – for single-use products and product samples.

- Flow packs – for portioning products such as food or cleaning agents.

Advantages of flexible packaging

Compared to many other types of packaging made from paper, glass or plastic, flexible packaging offers numerous advantages, such as:

- Flexible packaging is particularly lightweight, thereby reducing transport weight.

- lexible packaging saves space and therefore storage capacity.

- Flexible packaging offers a high level of product protection thanks to functional barriers.

- Flexible packaging is particularly sustainable due to its recyclable materials and low material usage.

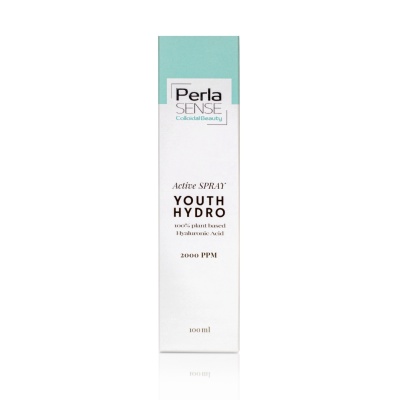

Folding boxes

Folding boxes

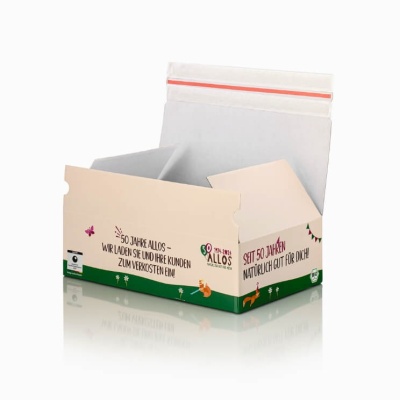

Shipping boxes

Shipping boxes

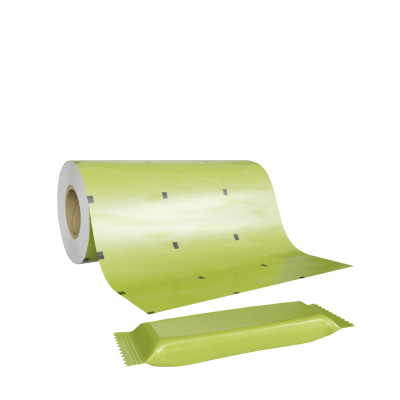

Stand-up pouch

Stand-up pouch

.png) Roll labels

Roll labels

Paper cans

Paper cans  Sample boxes

Sample boxes