The production of a folding carton is a complex, multi-stage process that can involve various manufacturing technologies depending on the type of carton and specifications. As standard, the production of a folding carton begins with the printing process, in which the desired folding carton design is printed onto a flat sheet of folding carton board. To make optimum use of the folding carton board, several folding boxes are printed on one printing sheet. The printed sheets then undergo various surface finishes, with different options such as varnishes, laminates or embossing available. The finished printed sheets are then die-cut and creased, excess material is removed and finally glued to form the specific type of box.

To ensure safe and smooth shipping, the finished folding boxes are carefully packed in cartons before being stacked on pallets for transport.

The production process summarised:

- Printing (offset or digital printing)

- Further processing

- Paint finish (glossy, matt, soft-touch)

- Partial coating (e.g. spot coating)

- Laminate (glossy, matt, soft-touch)

- Embossing (raised or recessed embossing)

- Hot or cold foil stamping

- Punching (conventional punching, laser punching)

- Breaking out (removing excess material)

- Bonding (single or multi-point bonding)

- Quality control

- Shipping

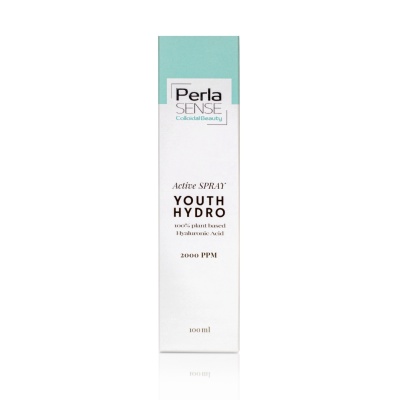

Folding boxes

Folding boxes

Stand-up pouch

Stand-up pouch

.png) Roll labels

Roll labels

Paper cans

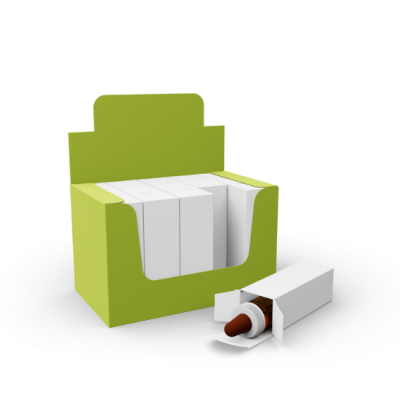

Paper cans  Sample boxes

Sample boxes