Made in Germany

Free Delivery

The FEFCO code 0713 stands for product packaging that is in a class of its own. Folding cartons that combine only the best: robust corrugated cardboard walls, a firmly glued crash lock base and therefore stable as well as particularly easy handling.

Properties and qualities, thanks to which these cartons are quite rightly positioned as a bestseller in our assortment - especially as packaging for heavy, fragile as well as serially produced goods.

Your individual FEFCO 0713 folding cartons with crash lock base:

American cardboard boxes made of corrugated cardboard FROM THE MANUFACTURER

Our packaging

Individuelle Versandverpackungen für einen sicheren Versand.

Individuelle Versandverpackungen für einen sicheren Versand.

CONTACT US

The essential feature of the FEFCO-0713 folding carton is the crash lock base. This consists of four glued flaps, which together form a particularly strong bottom closure.

The closing device at the lid opening, on the other hand, is similar to that of conventional folding boxes - it consists of two dust flaps and a lid flap with a tuck-in flap.

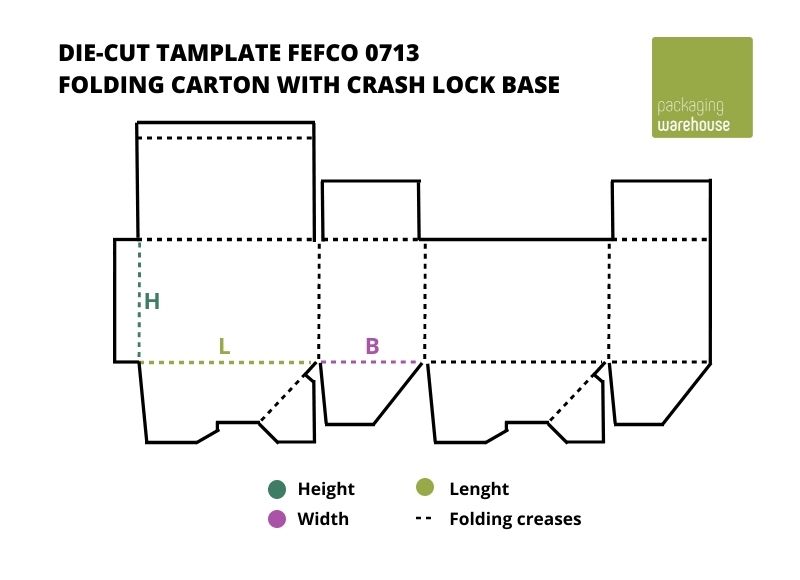

The entire carton consists of only one piece of corrugated cardboard. On the left edge piece there is a factory edge with a small protrusion, which is still glued to the opposite edge of the cardboard during production.

We deliver your ordered folding cartons glued and in a flat shape. The bottom flaps are arranged in such a way that they automatically move into position as soon as you turn the flat carton into a rectangular shape. So it only takes one handle to set up the FEFCO-0713 cartons. For this reason, crash lock bases are often called flash bases.

The lid opening, on the contrary, is closed in the same way as conventional folding boxes with a tuck-in flap. First you angle the two dust flaps, then fold the lid over them and finally fix it in place with the help of the tuck-in flap.

Tip: It is also possible to set up the boxes by machine - this will save you even more time when packing your goods.

Folding cartons are very versatile in terms of their look. Even during configuration, you can influence the final look of your packaging with your decisions. For example, you can freely determine,

you want. Our online configurator provides you with the corresponding selection options.

You have even more freedom when it comes to design with print and color. Our FECO-0713 folding cartons can be printed on all sides, inside and outside. If desired, it is also possible to individualize and personalize your cartons with the help of variable print data.

Simply by protecting the contents from damage, packaging makes an important contribution to environmental protection. However, corrugated cardboard packaging is an environmentally friendly solution in quite another way:

Apart from that, every order you place with packaging warehouse supports a social project - for example, the reforestation of German forests or animal welfare on local farms.

No tasks are too difficult for FEFCO 0713 folding cartons. Thanks to the combination of glued bottom flaps and thick corrugated cardboard walls, they are among the most robust types of boxes - and are therefore ideal as product packaging for heavy goods:

The corrugations also reliably absorb physical impacts such as shocks (e.g. during transport) - they provide a useful buffer for fragile goods in particular.

The type and number of glued corrugations are the main factors that determine the load-bearing capacity of your corrugated cardboard folding cartons. With us you have the choice of three different variants:

You have a free choice when it comes to the packaging format. At packaging warehouse, we produce not only standardized sizes, but also customized ones. You can determine the length, width and height of your cartons to the millimeter - provided that the desired dimensions are within the following minimum and maximum values:

Note: Please note that the specified maximum values can not always be combined for technical reasons. In this case, our online configurator will inform you immediately.

Depending on the size of the print run and your individual design requirements, we use either digital printing or the traditional offset process at packaging warehouse. The decision is always to your advantage.

In terms of print quality, by the way, both processes impress with sharp contours and rich colors. The differences in the printed image are hardly noticeable for non-professionals.

High-quality packaging not only protects the contents, but also attracts the interest of the target group and creates powerful buying impulses. Finishes such as varnishes and laminates are a useful addition with regard to the functions mentioned above.

On the one hand, they increase the surface's resistance to moisture, humidity, UV rays, dirt and scratches. On the other hand, they enhance the packaging in terms of its visual and haptic properties.

At packaging warehouse, you can choose from the following options for finishing your folding cartons: