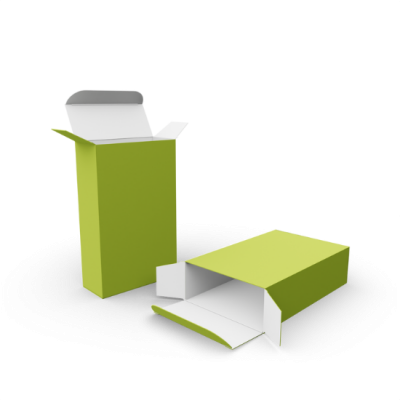

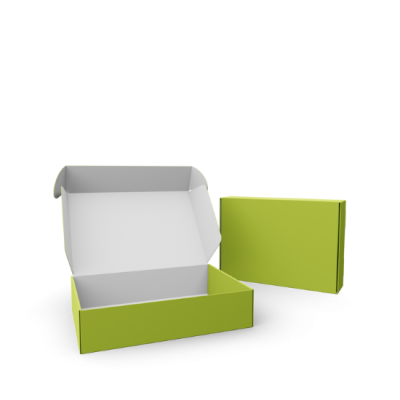

The automatic base is a folding box closure that assembles automatically when the folding box is set up. The automatic base is suitable for heavier products (solid board up to approx. 500 grams / corrugated board up to 32 kilograms). The base is glued during production using two adhesive dots so that no additional measures are necessary during assembly.

Advantages of a crash-lock base

The automatic bottom has many advantages over the tuck-in flap and the tuck-in bottom: it enables fully automatic and very fast assembly and packaging of the folding box. This makes the automatic bottom particularly suitable for large quantities, and the desired contents can be easily inserted using fully automatic packaging machines. In addition, the automatic bottom protects against unwanted access to the contents of the folding carton – this is required by law, especially for tobacco products such as e-liquids. Due to the two additional adhesive points for the bottom closure, the automatic bottom is more expensive than an insert flap or a plug-in bottom. The increased complexity caused by the two additional adhesive points makes it impossible for folding box gluing machines to produce at the same speed as when using an insert flap or a tuck-in bottom.

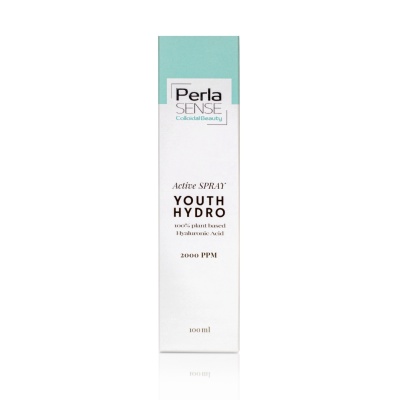

Folding boxes

Folding boxes

Stand-up pouch

Stand-up pouch

.png) Roll labels

Roll labels

Paper cans

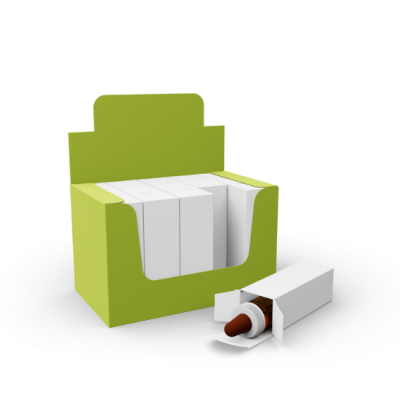

Paper cans  Sample boxes

Sample boxes