After the printing process, the printed sheets are further processed. This involves a comprehensive portfolio of technical processes that can be used to adapt the surface or texture of the printed sheets to individual customer requirements. Some technologies serve to enhance the functionality of the folding carton, while others are mainly used for visual and haptic effects and marketing purposes. The following further processing options are available.

Full surface coating

This involves applying a full-surface, abrasion-resistant coating to the entire surface of the printed sheet/cardboard. The coatings are available in different finishes – matt, glossy or soft-touch. Depending on the finish, it is often necessary to plan for a varnish-free area. This type of finishing is always recommended, as it provides additional protection for the printing inks and the folding carton material.

Partial paint

These are different types of partial surface finishing using various varnishes. The main distinction is between partial UV varnish and partial relief varnish (3D varnish). However, relief varnish is slightly raised and can be clearly felt to the touch.

Laminate flooring

This is a plastic laminate applied to the entire surface, which can have a positive effect on the appearance and feel of the folding boxes. In addition, the robust plastic laminate provides increased protection for the print image and the folding box material against external influences such as abrasion, dirt or moisture. Depending on the design, a laminate can also be applied to the inside of the folding carton to enable direct contact with food. The laminate also protects the cardboard from greasing through when handling highly greasy foods.

Hot or cold foil stamping

This is a very high-quality visual modification of the printed sheets by applying metallic foils in various colours such as gold, silver, bronze, blue, yellow, red, and many more. Depending on the technology used, this process incurs additional costs for tools or work steps, which vary in amount.

Each of the two technologies has different advantages and disadvantages. Cold foil, for example, can be applied from a line width of 0.05 mm and can be overprinted without any problems (a silver cold foil with different coloured overprinting produces different metallic effects). On the other hand, hot foil stamping usually has a higher degree of gloss and stands out due to its stronger haptic surface effects. In addition, hot foil stamping can also be applied to rougher surfaces – the adhesive used in cold foil stamping, on the other hand, requires a very smooth surface (e.g. a coated surface).

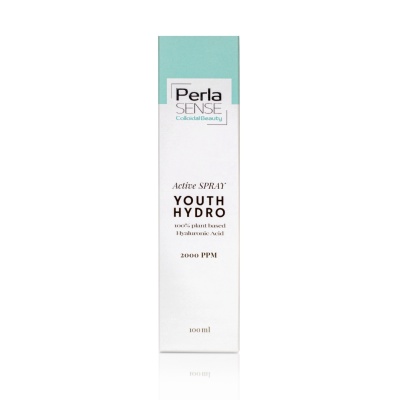

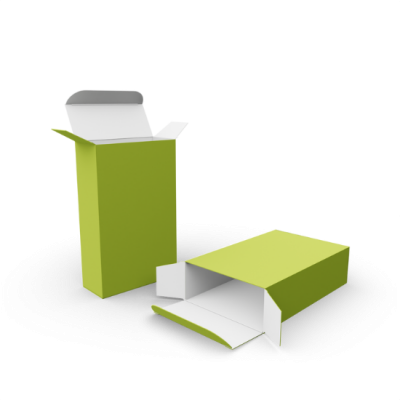

Folding boxes

Folding boxes

Stand-up pouch

Stand-up pouch

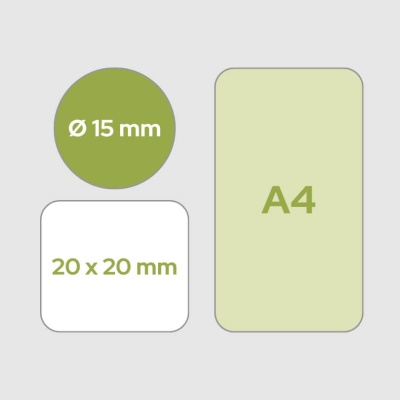

.png) Roll labels

Roll labels

Paper cans

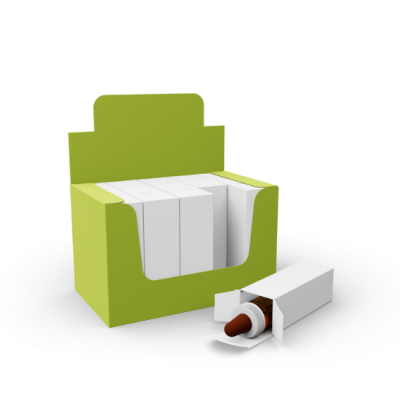

Paper cans  Sample boxes

Sample boxes