Gluing folding boxes is the final processing step in the manufacture of folding boxes. When the folding box is glued, it takes on its final shape and is then packed flat into cartons. The folding box can then be assembled and packaged.

The gluing of folding boxes is a mechanical process in which adhesive is applied at various points and different parts of the box are then joined together. The folded boxes are then pressed in the machine to ensure that the glued joints are secure and clean.

The speed of the gluing machine depends on the box size, the number of glue points and the complexity of the box type. A simple folding box with a longitudinal seam can be glued at a higher machine speed than, for example, a folding box with a crash lock base.

Adhesive dots

Depending on the type of box, different numbers of adhesive points are applied using nozzle or wheel application systems. A simple folding box with a longitudinal seam has one adhesive point. A folding box with an automatic bottom has three adhesive points (1 x longitudinal seam / 2 x automatic bottom). Depending on the gluing machine, different numbers of adhesive dots can be applied. The maximum number of adhesive points is 6 and is used, for example, in so-called six-point boxes – these are glued folding boxes with hinged lids that can be set up and filled relatively quickly.

Adhesive sample

Depending on the type of box, application (e.g. product weight) and application system, the adhesive can be applied in different patterns. The greater the forces acting on the material and the adhesive joints, the more adhesive must be applied. Common adhesive patterns are continuous adhesive joints, dashed adhesive joints of varying lengths or dotted adhesive joints in several rows.

Types of adhesive

The adhesive used is the key factor in successfully gluing a folding box. Many different factors must be taken into account when selecting the right adhesive. Depending on the application, adhesives for folding boxes must, for example, be food-safe or suitable for deep-freezing. Manufacturers must also ensure that application systems such as nozzles can be cleaned quickly and easily.

The surface of the material also influences the success of the bonding process. For example, painted or laminated surfaces cannot always be bonded easily. Depending on the type of adhesive, it may be necessary to roughen or mill the bonding areas. This ensures that the adhesive adheres well.

Contents mixed with essential oils can also affect the adhesive strength of some adhesives. If, for example, teas or bath salts are to be packaged, check whether they contain essential oils – special adhesives are available for these cases.

- Water-soluble adhesives: mixture of water/solvent and protein/starch

- Dispersion adhesive: dispersion of water and plastic particles

- Hot melt adhesive: Thermoplastic material and additives such as resin or wax

Folding boxes

Folding boxes

Stand-up pouch

Stand-up pouch

.png) Roll labels

Roll labels

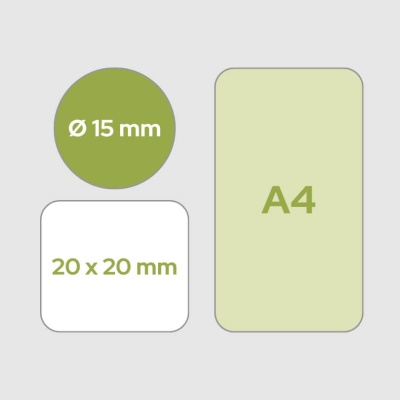

Paper cans

Paper cans  Sample boxes

Sample boxes