Made in Germany

Free Delivery

Highest quality

Configure Flat Pouches

Flat Pouches

INTERESTING FACTS

Flat pouches in use

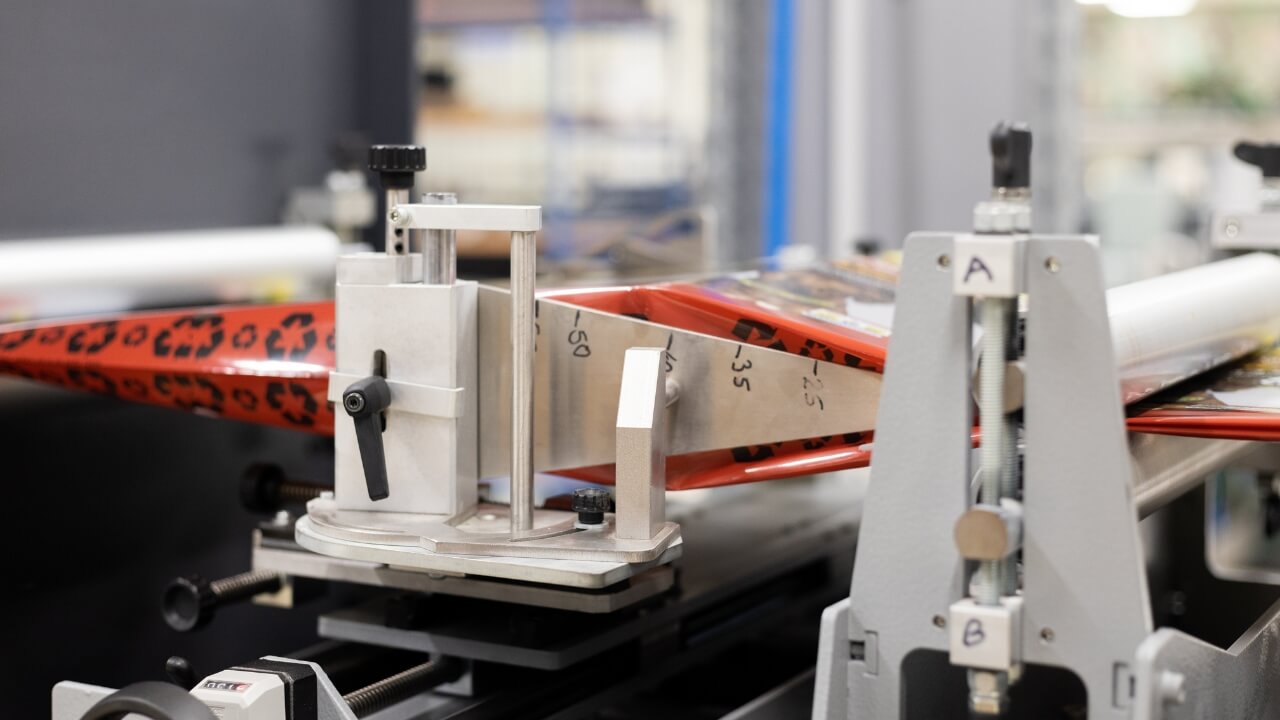

Flat pouches FROM THE MANUFACTURER

Packaging Warehouse offers a wide range of materials for Flat Pouches to meet a variety of needs and requirements. Our range of materials includes:

Our range includes Flat Pouches with special viewing windows, which are mainly made of transparent film materials. These pouches are printed according to specific requirements, with certain sections left unprinted as viewing windows. An additional opaque white coating enhances the intensity of the printed areas and improves the opacity of the colours. Flat Pouches of this type are particularly suitable for products that need to be directly visible at the point of sale, such as packaging for pet food, foodstuffs or medical products. The ability to see the contents directly can increase consumer confidence in the product and positively influence the purchase decision.

In addition to customisable viewing windows, we also offer Flat Pouches with different surface finishes. Metallised surfaces create striking metallic effects in the selected colours. To ensure that certain colours and elements do not appear metallic, they are underlaid with a special opaque white. Customers also have the option of choosing between different surface finishes for all film materials, whether matt or glossy. These options allow for even more customised packaging design to specifically increase the attention of the target group.

Packaging warehouse's Flat Pouches are not only versatile in their choice of materials, but also in their configuration options. Customers can choose from a range of formats, whether one of our fixed standard formats or a completely customised format that is tailored precisely to the product. In addition, we offer the option of printing the bags over their entire surface and customising them, either using digital printing for the highest quality and precision or by adding features such as zippers, viewing windows or Euro holes, which not only increase the functionality but also the attractiveness of the packaging.