Pharmaceutical packaging FROM THE MANUFACTURER

Your partner for Pharmaceutical packaging

Pharmaceutical packaging

Made in Germany

We value regionality and love for our homeland. That is why your packaging is produced in the heart of Germany.

Sustainable materials

We rely on sustainable materials that are fully recyclable, PPWR-compliant and CO₂-saving.

Personal contact person

You will have a direct contact person at all times who will advise you individually and accompany you from enquiry to delivery.

Our packaging

Matching packaging for Pharmaceutical packaging

Shipping packaging - e-commerceIndividuelle Versandverpackungen für einen sicheren Versand.

Hochwertige Materialien

GLS boxesIndividuelle Versandverpackungen für einen sicheren Versand.

Hochwertige Materialien

>4000 CUSTOMERS PLACE THEIR TRUST IN USTurn your Pharmaceutical packaging into a game changer!

Do you need Pharmaceutical packaging that suits your product? We'll take care of it – no matter whether it's small, large or really sophisticated. We have been printing in Germany for three generations, combining experience with modern technology. You get quality you can rely on and people who think for themselves. Together, we'll turn your idea into the perfect packaging.

CONTACT US

How can we help you?

Designed for the highest demands: Our pharmaceutical packaging

Due to the legal regulations to which pharmaceutical packaging is subjected, our demands in this segment are particularly high. Auch hier können wir unsere Kunden optimal in diesem herausfordernden Prozess unterstützen. Here, we can also optimally support our customers in this challenging process. We succeed in this not only because of our strong understanding of the quality of our products, but also because of the technology we have at our disposal.

Whether lasered first-opening protection or consecutive numbering: thanks to our punching and laser technology as well as digital printing, we are the perfect partner to implement this challenge in a high-quality and cost-efficient manner. In addition, we work exclusively with HACCP-certified manufacturers.

The requirements for pharmaceutical packaging are diverse:

- In turn, seniors should have easier access and handling.

- Packaging for pharma articles must be marked with an individual and consecutive number, a first-opening protection (for example in the form of an adhesive seal) and a scannable matrix code.

- In addition, the sensitive products must be protected from unauthorized access by children.

- Pharma packaging must also list the most important instructions in Braille.

- The HACCP concept ensures compliance with the high quality standards for safe food.

We cover all of these factors at packaging warehouse - with our special packaging offering for the pharmaceutical industry.

The german drug law

Until the establishment of the German Ministry of Health in 1961, parts of the pharmaceutical law were governed by various regulations. It is since 1961 that there has been a special pharmaceutical law, which has since defined all these legal regulations in a uniform manner.

The original version of the law initially dealt only with the registration of pharmacological products. In order to keep the German pharmaceutical industry competitive on the global market, extensive testing of products by the Federal Health Office was dispensed with. It was not until 1964 that pre-clinical as well as clinical studies became mandatory. A universal guideline according to which products must be tested was adopted in 1971.

As a result, the German Drug Law has gradually been subjected to increasingly stricter rules. For example, the indication of an expiration date has been mandatory in Germany since 1986, or the printing of the drug name in Braille since 2004. In the course of time, further criteria were added, which mainly affected pharmaceutical packaging. Today, for example, they must meet the following criteria:

- Printing of all information in understandable language as well as in durable and well readable font

- Marking with approval, batch and individual serial number

- Deposit of all information in a scannable code

- First-opening protection

Accessibility for visually hadicapped people

The printing of the drug name in Braille has not only been specified in the AMG as a mandatory feature of pharmaceutical packaging since 2004 - the specification of the drug name in so-called Braille is also prescribed in the European Human Code. In order to guarantee a durable, good and fast feel, the letters must be printed in a high quality.

The quality of the material plays a major role here, because Braille is easier to read on smooth surfaces than on roughened surfaces. The height of the embossing points as well as their distance from each other also affects how well the information can be analyzed.

Leicht handhabbare Pharmaverpackungen für Senioren

Because the need for pharmaceuticals increases with age, seniors make up a disproportionately large share of consumers for pharmaceuticals. For this group, it becomes increasingly difficult to handle drug packages as they age and their motor skills become less efficient.

Due to declining eyesight, it is also becoming more and more challenging to read the information correctly and therefore to remove the medicines from the packaging in the correct dosage. Therefore, packaging for medicines for the elderly should be barrier-free, safely accessible and meet the following criteria:

- well readable information

- easy to open and close

- no risk of injury due to sharp edges

- easy removal of individual dosages

In addition, the imprint of an RFID, NFC or QR code can take on several functions in the future: Scanning with a smartphone or via digital displays not only provides information such as the date of the initial opening or the number of quantities removed: Seniors can use the codes to have the package insert and other information played out or read aloud to them individually.

Protection from external influences

Pharmaceutical products are very diverse in their properties and can be produced in different aggregate states, for example:

- in powder form

- in tablet form

- in liquid form

- as cream

In addition, there are drugs for external use such as special patches or bandages. What they all have in common, however, is that a high level of barrier resistance is required to protect these sensitive products from external influences. Among other things, pharmaceutical packaging ensures that products do not become contaminated or contaminate other items. At packaging warehouse, we always focus on barrier resistance, no matter what type of packaging is concerned. Our pouch materials meet high requirements for the following barriers:

- Oxygen barrier

- Water vapor barrier

- Aroma barrier

- UV barrier

This means that your items are optimally protected from external influences with our pharmaceutical packaging and can be shipped safely.

Protection during transport and safe storage

Our shipping boxes in high grammage and thickness perfectly protect your medicines and medical devices in case of shocks, pressure or falls.

Another special feature for pharmaceutical products is their storage. Unlike conventional consumer goods, cryogenic cooling may be required. In order to optimally protect the products even at temperatures around -250 degrees Celsius, it is important to choose the right packaging. We will be happy to explain to you in a consultation which materials provide your products with optimum protection - together we will find the best solution.

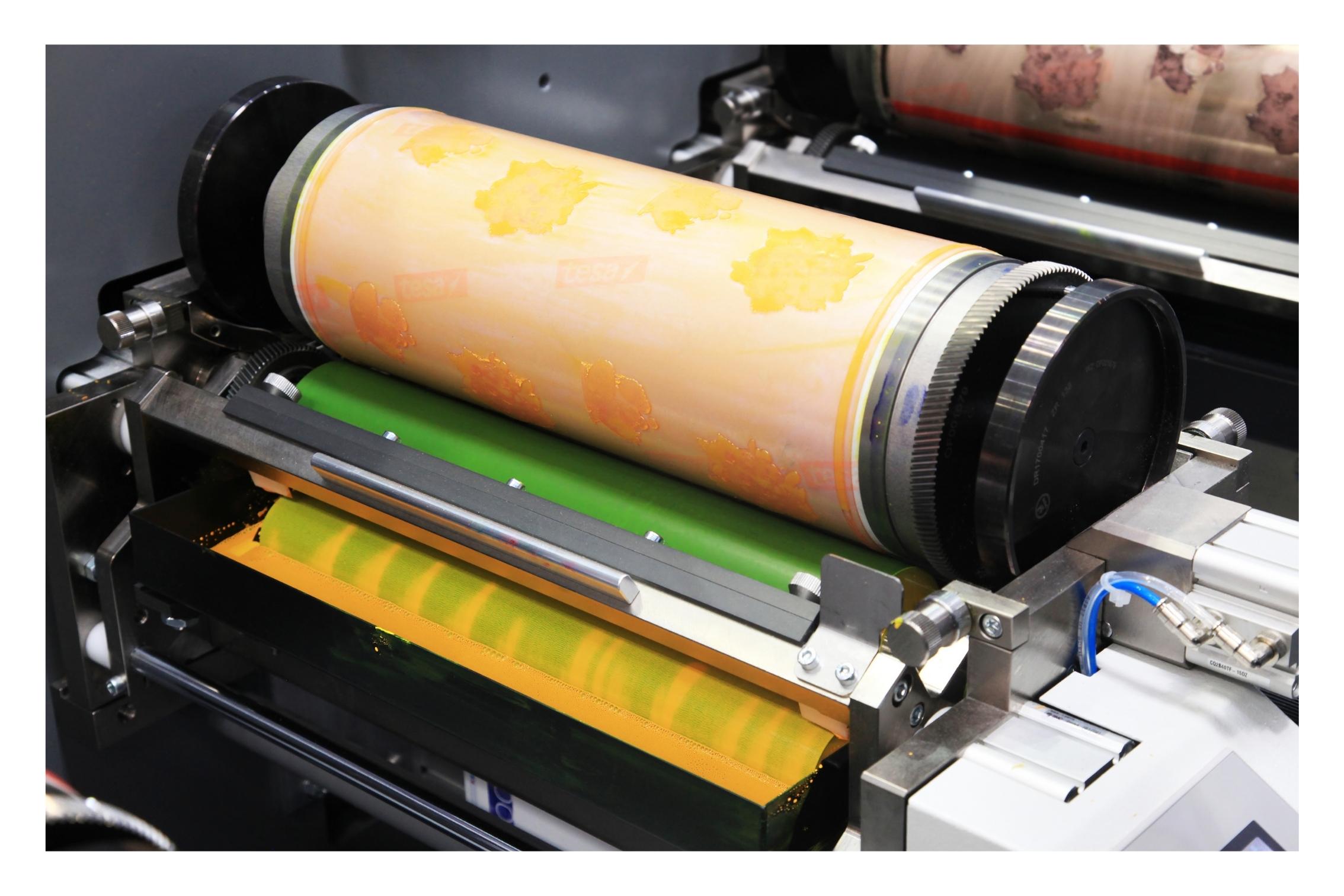

Highest quality print results

At packaging warehouse we use offset and digital technology to print our packaging. Digital printing is a particularly good and efficient way of meeting special requirements for pharmacy packaging. This is because, unlike offset printing, digital printing does not require any aids such as printing plates. The file to be printed is read electronically, for example from a storage medium, which has various advantages:

- Printing requires only a few preparation steps.

- Changes to the printed image are possible at short notice.

- Due to the absence of a static printing plate, the process is in general cheaper and faster.

- Digital printing delivers a very high-quality print result and can display fonts with high contrast and good readability.

The decisive advantage of digital printing for pharmaceutical products, however, is the high degree of customizability. Due to the legal regulation of the Drug Law, the individual, consecutive product number must be printed on each package. Unlike offset printing, digital printing makes it easy to customize this consecutive number for each pharmaceutical package - and it's absolutely cost-efficient, even for small quantities.

Packaging Warehouse: Our special packaging solutions for the pharmaceutical industry

LARGE CHOICE OF MATERIALS: All our pharmaceutical packaging is available in different materials and designs, which you can select and combine yourself in the configurator. So you decide for yourself which type of paper (pulp, recycled, grass, natural or chromo cardboard) and which additional protection (protective varnish, protective laminate) best suits your application.

FREE SIZES AND FORMATS: Among other things, we have specialized in implementing individual customer wishes exactly. In our configurator, you can determine the right format and size for your area of application.

FIRST-OPENING PROTECTION: We have various customized solutions to implement the mandatory first opening protection. By using a laser, it is possible to integrate a perforation as a pre-determined breaking point at which the pharma packaging is opened. Protection can also be achieved with an adhesive label that acts as a seal.

BRAIL LETTERING PRINTING: The state-of-the-art machines we use are capable of printing type markings in Braille in the specified standards in terms of character spacing and embossing height. Through a final quality check, we ensure that there are no spelling errors. Our materials with particularly smooth surfaces additionally provide a low-barrier for people with visual impairments.

HIGH QUALITY PRINTING: Our digital printing technology enables durable and highly readable type with sharp edges and high contrast. The printed products are also highly customizable and allow for cost-effective printing of a consecutive serial number. We offer double-sided four-color printing in all Euroscale color tones - with outstanding qualitative results.

Our product range

Folding boxes

These packaging classics are especially suitable as outer packaging for pharmaceutical products. Whether blisters, vials, jars, tubes or similar: In our Folding boxes all products are optimally secured against external influences such as impacts or falls and can also be used quite easily for the presentation of goods. They are available in various basic designs:

with snap lock base - slightly stronger than boxes with tuck-in flap

with crash lock base - thanks to glued bottom especially load bearing

with tuck-in flap - especially suitable for light packaged goods

with Euro slot hanger - perfect for the presentation of goods on standardized hangers

Stand-up and flat pouches

Pouch packaging is the ideal choice for liquids, capsules or powders and offers high barrier performance. After filling, they are sealed airtight to provide an insurmountable barrier to oxygen, steam, flavors and UV radiation.

The pouch packaging for pharmaceutical products are available in various sizes and optionally with Euro perforation or round perforation. Our selection includes doypacks, K-bottom pouches and flat pouches - in the following styles:

- with tear flap

- with PE zipper - for easy opening and reclosing

- with suspension (hole suspension or Euro slot hanger)

Shipping boxes

To ensure the safe shipment of sensitive goods, our shipping boxes are the perfect solution for items from the pharmaceutical sector. Thanks to the strong corrugated cardboard, they guarantee complete protection during transportation. They also allow stacking and shipping of multiple items and, depending on the type of flute, are designed for a transport weight of up to 32 kilograms.

Our shipping boxes are available in the following variations:

- with hinged lid

- with folding base

- with crash lock base

- with tear tab

- with additional adhesive strip for returns (e.g. as packaging for online mail-order pharmacies)

Euro slot hanger

In combination with a glued or welded plastic film former, Euro slot hanger are ideal for all medical products that need to be packaged under a sealed protective cover but visible to the consumer. The hangers are also a useful extension to other packaging such as folding boxes.

Due to standardization, all items that have Euro perforation are easily compatible with all suspension systems of the same standard. Euro slot hangers can be used to present your products directly in the checkout area of drugstores or pharmacies. Therefore, they are the perfect solution especially for POS items.

Labels

Labels for pharmaceutical products have special tasks - because they also function as first-opening protection. For this purpose, they are stuck over the opening of the pharmaceutical packaging as a seal. Our roll labels made of foil are particularly suitable for this purpose. They can not be peeled off in one piece and therefore provide very good security.

The lettering on labels must be high-contrast and easy to read - throughout the entire period of use. Printed in different colors, they help the elderly in particular to differentiate their medicines and minimize the risk of confusion. High resistance to moisture, alcohol, mechanical influences and light chemicals is also particularly important for medical product packaging.

Counter displays

They are not only used for the safe transport of goods, but also function as an individually printable sales surface at the point of sale. The counter displays allow pharmaceutical products to be presented efficiently, effectively and in a way that attracts attention.

The hinged cardboard lid can be used as additional advertising space and printed as required. This is the ideal way to present your products. Counter display packaging is available in the following variants:

- with snap lock base

- with crash lock base

Pillow boxes

They generate attention at the point of sale due to their eye-catching appearance. Pillow boxes are also very cost-effective to produce and are suitable for all less sensitive or shrink-wrapped products.

Typical examples of use are earplugs, patches, facemasks or single-use gloves.