The basis weight (grammage), also referred to as surface-related mass, is specified in grams per square metre (e.g. 400 g/m²) and is calculated as follows:

Area-related mass (g/m²) = sheet weight (g) ÷ sheet format (m²)

The basis weight plays an indirect technical role, as changes in basis weight also alter other important properties of the cardboard, such as its thickness and specific volume. The basis weight is measured in accordance with the guidelines of DIN EN ISO 536, as described in the technical guideline ‘Quality characteristics for folding boxboard’.

Folding boxboard is manufactured in a wide variety of designs. Most types of cardboard are available in different grammages depending on the intended use. The stability and bending stiffness of a cardboard box depend indirectly on its surface area mass, which means that the suitability of a cardboard box for the weight of its contents can increase with increasing grammage. However, another factor influencing bending stiffness can also be the composition of the cardboard (primary or secondary fibre, thickness/volume, number of layers, etc.) – for example, GZ cardboard made from primary fibre with a weight of 350 g/m² is often more stable than GD cardboard made from secondary fibre with a weight of 400 g/m².

Source: Trade Association for the Folding Carton Industry E.V.

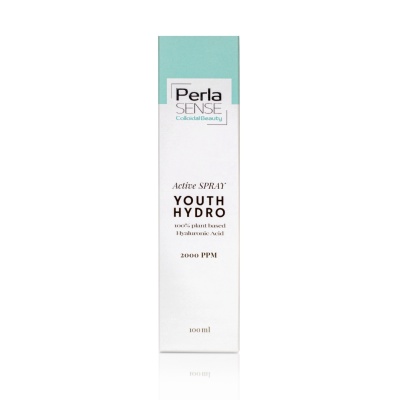

Folding boxes

Folding boxes

Stand-up pouch

Stand-up pouch

.png) Roll labels

Roll labels

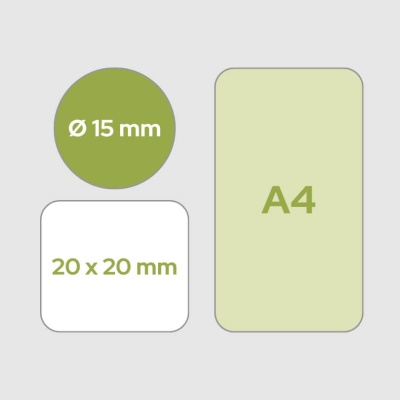

Paper cans

Paper cans  Sample boxes

Sample boxes