Made in Germany

Free Delivery

Cardboard boxes should protect your products safely while offering a professional unboxing experience. Our boxes can be printed over the entire surface, manufactured in custom sizes and equipped with sturdy E, B or EB-flute cartons as well as practical tear-open and adhesive strips. Thanks to express production starting at 5 working days, you benefit from maximum flexibility, brand impact and fast delivery.

Configure SHIPPING BOXES

Cardboard Boxes

Interesting facts

ENTDECKE UNSERE Kartonvielfalt

Individuelle Versandverpackungen für einen sicheren Versand.

Individuelle Versandverpackungen für einen sicheren Versand.

Individuelle Versandverpackungen für einen sicheren Versand.

Individuelle Versandverpackungen für einen sicheren Versand.

.png)

Individuelle Versandverpackungen für einen sicheren Versand.

Cardboard Boxes directly FROM THE MANUFACTURER

In 2021, Deutsche Post alone delivered more than 1.8 billion parcels. In total, the number of shipments transported annually by all courier, express and parcel services throughout Germany exceeds 3 billion. High-quality shipping boxes play a crucial role in this.

Cardboard boxes are logistically efficient and effective promotional packaging. When transporting goods, the choice of packaging material is therefore crucial. For example, corrugated cardboard is an excellent choice as a packaging material. Corrugated cardboard packaging is versatile, whether for transport, storage or product packaging – it is a stable, versatile and environmentally friendly material.

Corrugated cardboard is very flexible and versatile. These packaging solutions are the largest category among all paper, cardboard and paperboard packaging. They are also the market leaders in the shipping and transport industry. What's more, the cardboard boxes can be adapted to your individual requirements in almost every respect. From size and material to finishing, with us you have complete freedom in designing your individual Cardboard Boxes!

With cardboard boxes from packaging-warehouse, you get modern and environmentally efficient packaging that meets the highest standards.

To ensure that products can be transported cost-effectively and safely, shipping boxes should fit the product as well as possible. At packaging-warehouse, you can independently control complex processes, such as creating a shipping box. With the help of our intelligent configurator, you can easily coordinate everything in a clear manner – regardless of whether you are already a packaging professional or are new to the subject.

The intelligent configurator automatically makes some settings to make the entire process as clear and simple as possible for you. For example, it always selects the printing technology that is the most cost-effective solution for the desired order quantity. Of course, you can change these settings at any time. There are many other tools available to help you design your box perfectly, such as size selection, interior and exterior printing, and coating options.

Another feature that sets our service apart is the cost-effective production of small print runs thanks to digital printing technology. The flexibility of digital printing even allows for individually printed small runs, for example with consecutive serial numbers.

What's more, our express production service means your order can be produced in just 5 working days and tailored to your product thanks to the free formats.

Due to their versatility, corrugated cardboard boxes are used in almost all industries, including the chemical industry, beverage manufacturers, consumer goods industry, cosmetics industry, food and luxury food industry, and the pharmaceutical industry. This is because the different requirements of trade and industry pose no problems for the number one transport packaging material. Whatever you want to pack and ship, it will be in good hands in a corrugated cardboard box! Our specialists at packaging warehouse will be happy to advise you on which shipping box is best suited to your product.

Different products require different packaging. It depends on whether the goods are solid, liquid or powdered. In addition, the question arises as to whether the packaging must be oxygen-, moisture- or aroma-tight and whether it must be protected against temperatures, pressure, scratches, spoilage and substance changes. Furthermore, different goods can also be combined in one shipping carton.

In the following paragraphs, we would like to introduce you to some of the industries in which corrugated cardboard Cardboard Boxes can be used.

The food industry is one of the largest consumers of corrugated cardboard transport packaging. Almost all foodstuffs can be shipped safely in such cardboard boxes. Around 50 per cent of packaging is used in the food industry. In this case, that means:

Delicate fresh produce such as fruit and vegetables are optimally protected by the sturdy boxes at all times – the food remains undamaged during loading, temporary storage and transport.

Cardboard boxes from corrugated paper can be treated in such a way that they have no impact on the properties of the packaged food and prevent the migration of harmful substances.

Baked goods, sweets, flour, sugar, pasta, rice, beverage bottles – with our cardboard boxes, you can safely and efficiently package a wide range of different food and luxury items.

Both food producers and packaging manufacturers are equally responsible for complying with the legal framework governing food safety.

In addition to the food industry, other important customers for corrugated cardboard transport packaging are the chemical industry and agriculture. In these sectors, the main focus is on providing optimum protection for products both externally and internally.

The products of both industries must be protected from external influences such as moisture and dirt. Conversely, in many cases it must be ensured that the products do not escape through the barrier of the packaging (e.g. in the case of potentially hazardous substrates, fertilisers, etc.). Otherwise, depending on the chemical, there may be risks to humans and the environment.

As corrugated cardboard is a high-performance and durable material, it can also compete in these areas without any problems. With the right combination of corrugation and base type, our cardboard boxes can handle shipping weights of up to 32 kg.

Electronic devices are particularly popular in online retail. Retail will continue to expand. This has become particularly apparent as a result of the lockdowns during the coronavirus pandemic in 2020/2021.

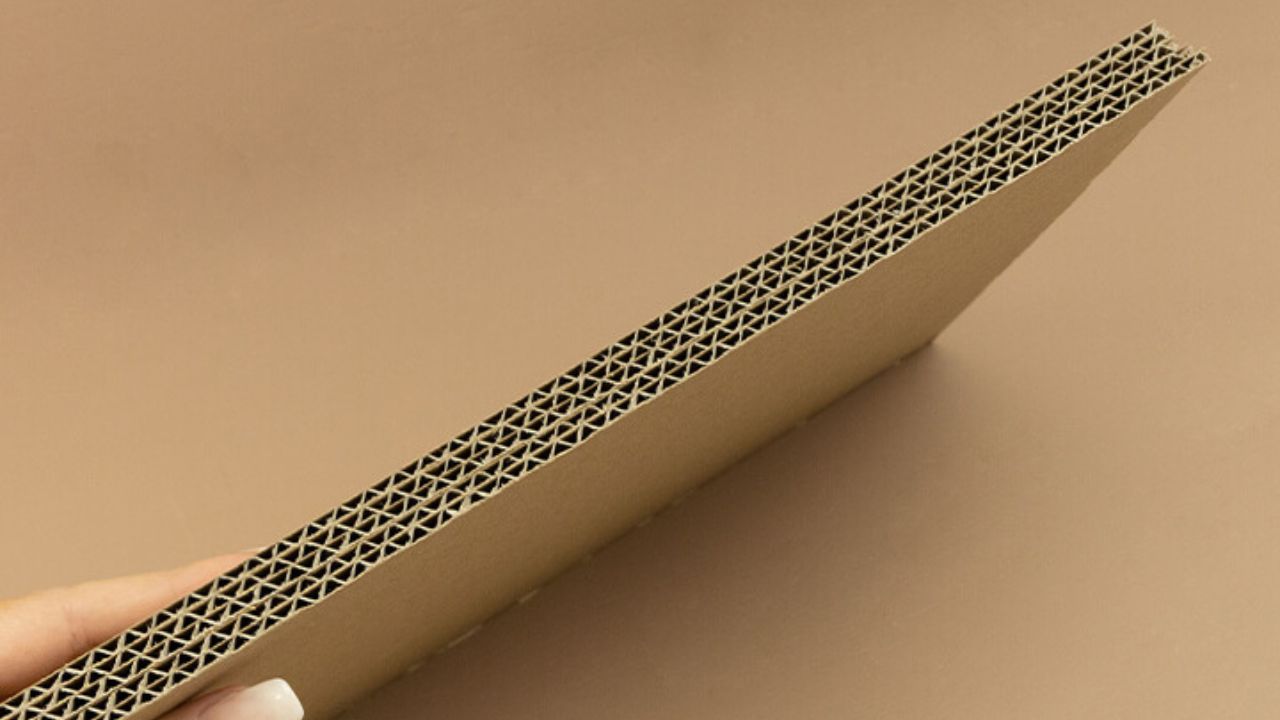

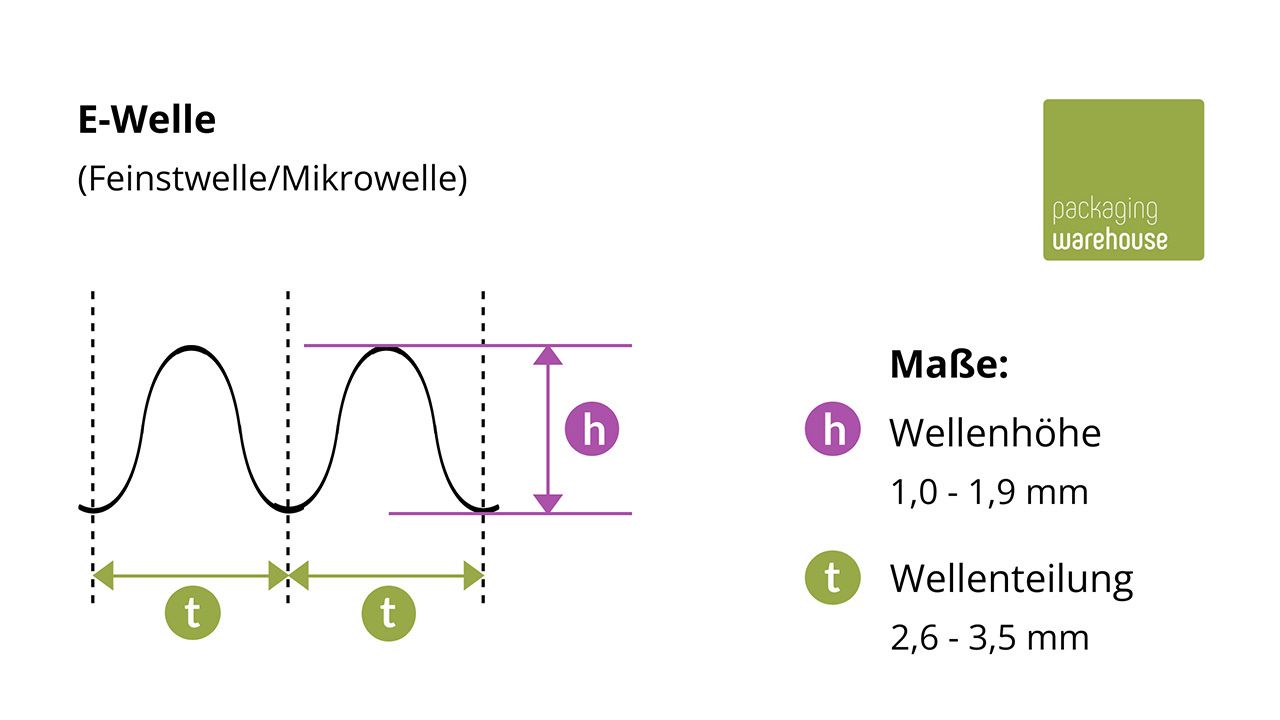

Not all corrugated cardboard is the same. Although the principle behind the name is always the same, there are different types of corrugation. Depending on their structure, individual types of corrugation are better suited to certain applications. That's why our range offers you a choice of several types of corrugation, allowing you to put together the cardboard boxes that offer the best properties for your needs.

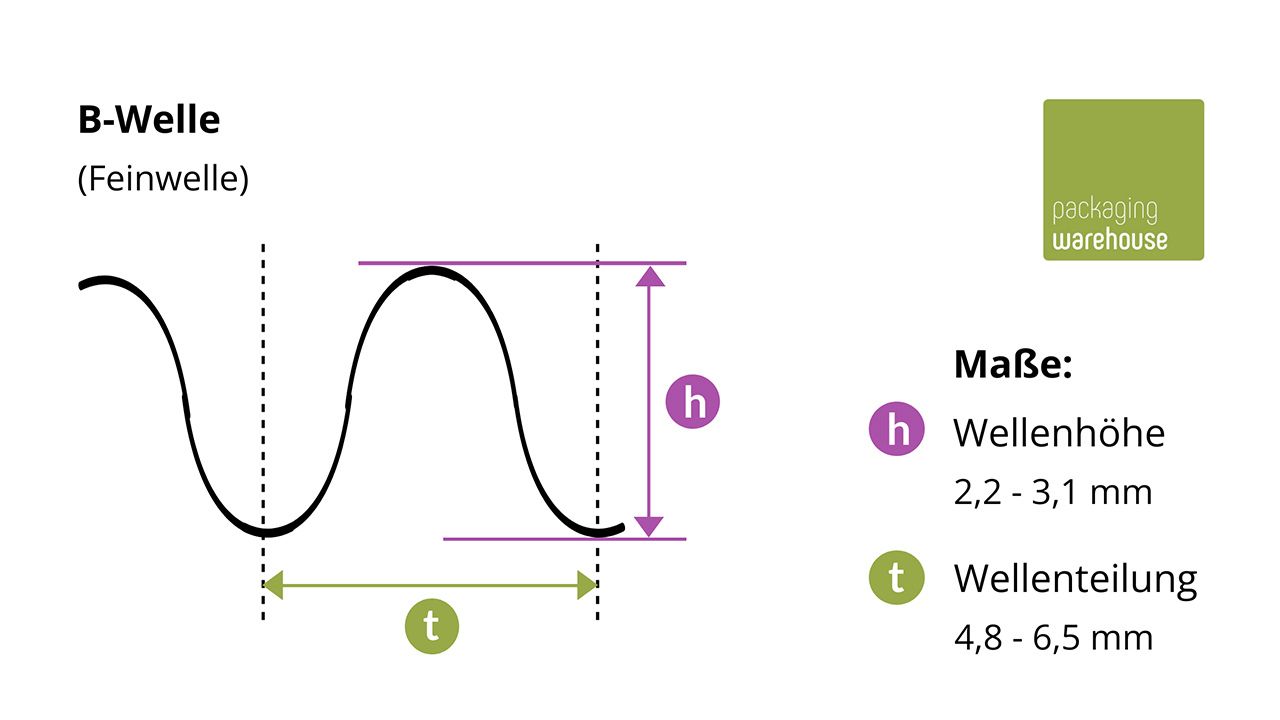

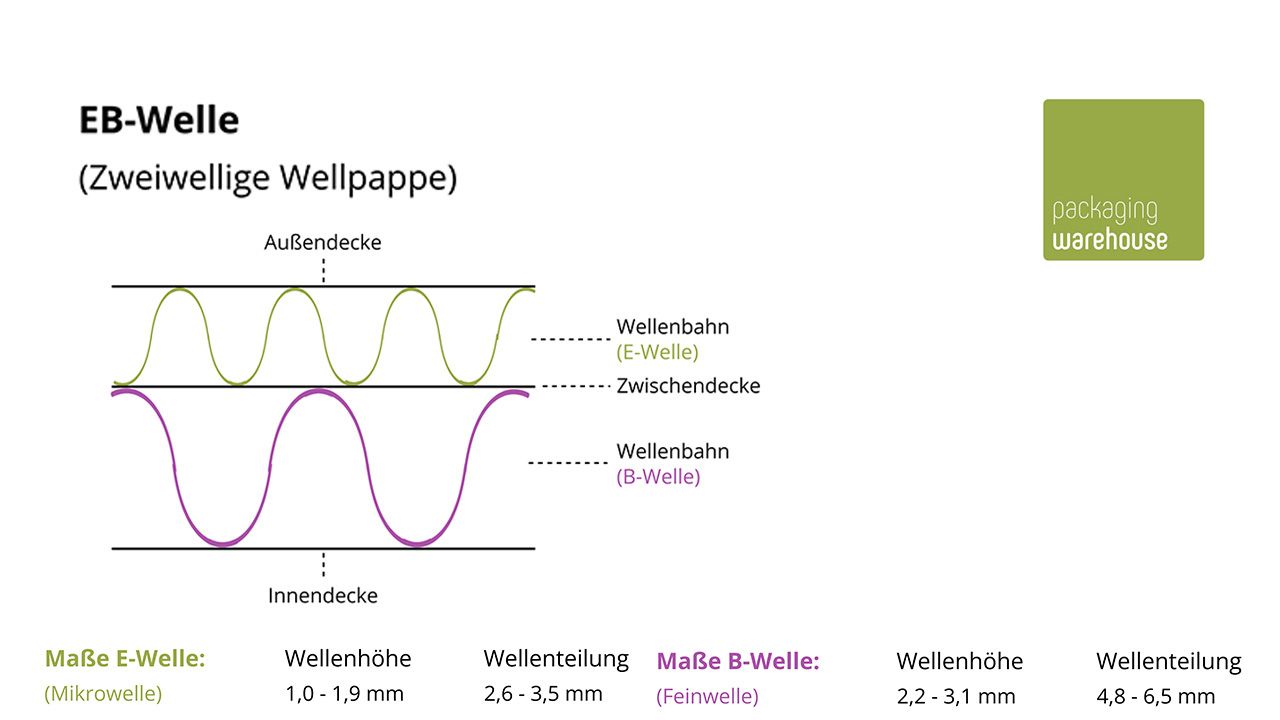

Corrugated cardboard is generally available in single-wall or multi-wall (double-wall or triple-wall) versions. More flutes always mean more layers of paper and thus greater stability. The larger and heavier the shipping carton, the more flutes should be used. In addition to the flute layers, there are also different types of flutes. These have their own flute pitch (t) and flute height (h). This refers to how high the flute is and how far apart the adjacent flute peaks are.

At packaging-warehouse, we use E, B and EB flutes for our cardboard boxes. This guarantees a wide range of possible uses.

Bei packaging warehouse findest du eine große Auswahl an Faltschachteln aus Wellpappe:

American cardboard boxes - FEFCO 0201 are also very easy to fill automatically and are available in the following versions:

The tuck-in flap (FEFCO 0211) is a simple and practical solution for sealing corrugated cardboard packaging. The tuck-in flap prevents the base and lid from opening by themselves – without the need for additional sealing material.

.jpg)

To secure products or present them appropriately, packaging warehouse offers a wide range of inlays and slipcases that can be perfectly combined with all boxes and cartons:

Our cardboard boxes at packaging warehouse can be customised according to your ideas and wishes. You can easily and conveniently design your own shipping box with our intelligent configurator!

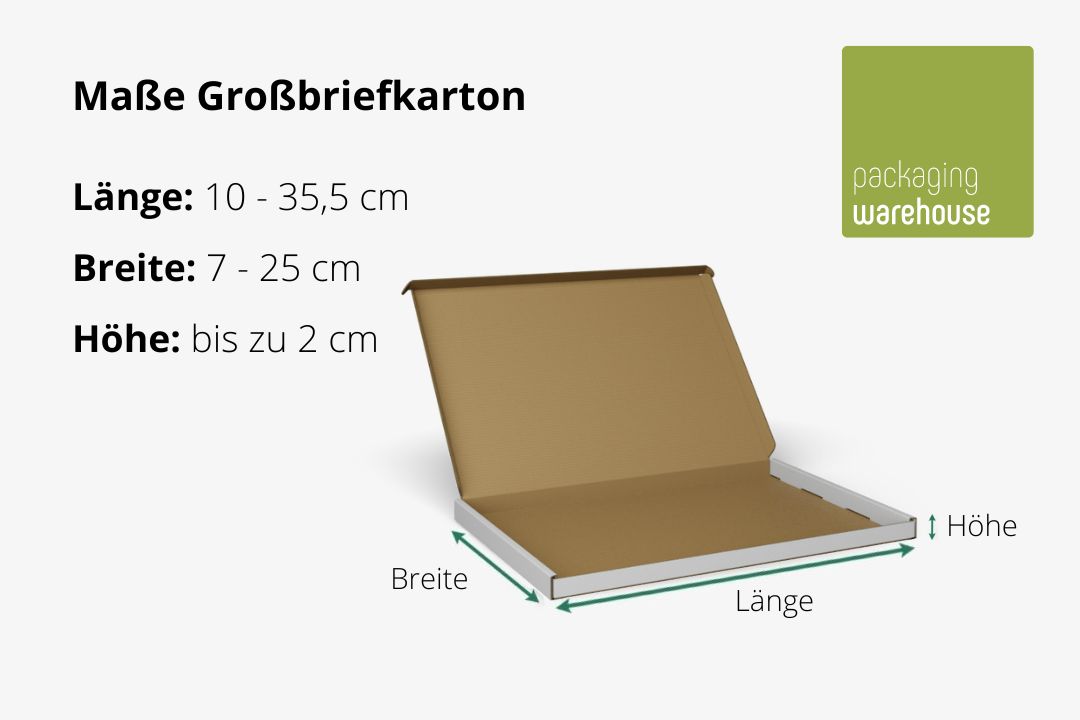

More freedom: All shipping and product packaging from packaging-warehouse is available in your desired format. Under ‘Size’, you can adjust the length, width and height of the boxes and cartons to suit your product.

More creativity: The cardboard boxes can be printed over their entire surface. This allows you to incorporate your designs and create packaging with a unique look and real recognition value. Feel free to send your print data to packaging warehouse. We will advise you on how to achieve the best possible result.

More protection: Your customised cardboard boxes will make an even bigger impression if you apply a protective coating or laminate – available in either a glossy or matte finish. Both protect your box design from scratches and dirt during transport and also contribute to a particularly high-quality look.

By the way: if you only order small quantities of cardboard boxes, packaging warehouse guarantees fast production times. This saves you long waiting times for shipping and product packaging. Top quality in a short time – we at packaging warehouse make it possible for you!

To protect your cardboard and the print image even better from scratches, you can choose between two coating options in our configurator:

A thin layer of varnish on your shipping box ensures that the print image is not damaged by scratches, dirt or even liquids. There is also another advantage: the gloss makes the print stand out even better and protects it from fading due to sunlight. The print image itself appears more detailed and high-quality thanks to the varnish. Our protective varnish is available in both matt and glossy finishes.

Here, the cardboard is not coated with a varnish, but covered with a thin film. This makes the outside even more resistant to external influences and also protects the print image from scratches and UV radiation. Our laminate is also available in matt or glossy. It offers the highest level of protection and, just like the protective varnish, enhances the print image.

Both finishing options are available in our intelligent configurator and give your shipping carton an elegant and protective finish.

For us, sustainability is a central tenet of our company philosophy. That is why all our materials are sustainable in nature:

In addition, our corrugated cardboard is characterised by resource-saving and energy-efficient production. Almost no trees are felled in corrugated cardboard production. The primary raw material for paper production is obtained from broken and thinned wood during the maintenance of managed forests.

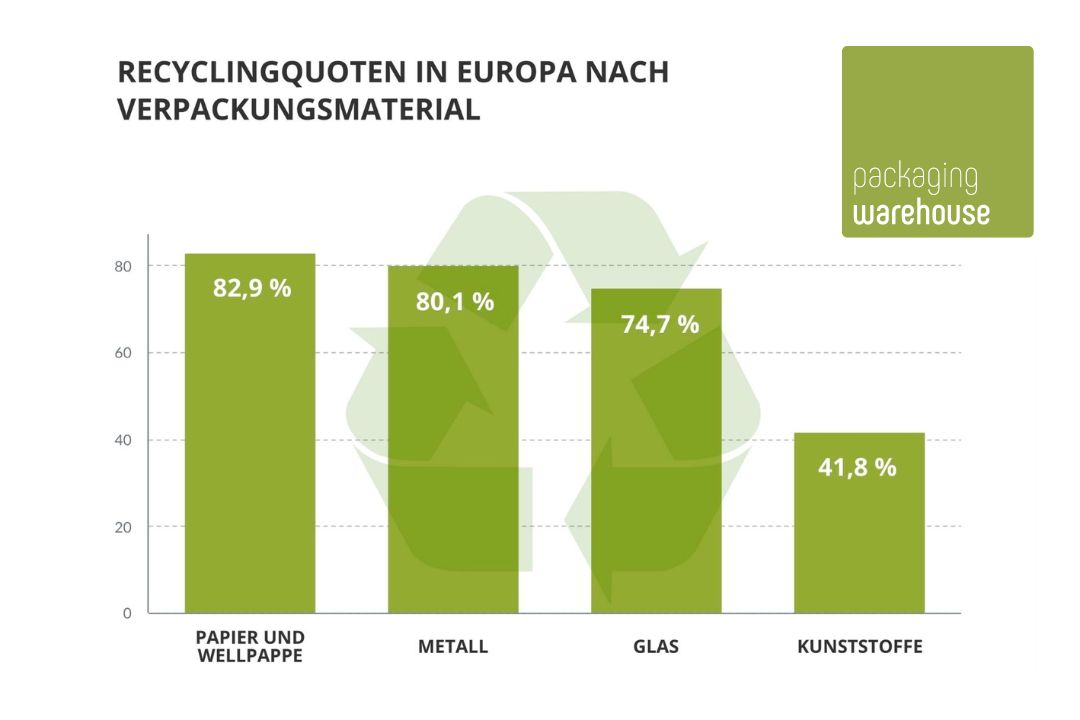

Another advantage of corrugated cardboard is its recyclability. Once adhesives, impregnations and other chemicals have been removed from corrugated cardboard, it can be almost completely recycled. Approximately 80 percent of the annual production volume therefore consists of recycled material. Cardboard fibres can theoretically be recycled up to 25 times. However, the fibres become shorter with each new cycle. Therefore, fresh fibres must always be added during corrugated cardboard production to prevent a loss of quality in the end material. In the United Kingdom, however, only 20 per cent of fresh fibres are used for corrugated base paper.

Energy consumption in corrugated cardboard production is also significantly lower than in glass recycling. In addition, there is less chemical waste than in plastics recycling.

However, due to the effort involved, offset printing is only cost-effective for orders above a certain quantity, as additional costs are incurred for creating the printing plate and for consumables.

In digital printing (xerography), data is transferred directly from the digital database (e.g. via data transfer from the cloud or via a USB stick) to the packaging. The advantage here is that, as the process is not as complex as offset printing, even smaller print runs can be produced cost-effectively. The printing inks are liquid or powder-based.

Thanks to digital data transfer, it is easy to make individual adjustments within a series, such as printing a consecutive serial number. With offset printing, this would involve very high costs and a considerable amount of time. A new printing plate would have to be produced each time. Digital printing is therefore the ideal solution for printing cardboard boxes in smaller runs of 1 to 500 pieces.

A third printing process that we also offer is known as ‘flexographic printing’ – another direct printing process that is particularly suitable for large print runs of 25,000 boxes or more.

When putting together your desired product, our intelligent configurator automatically selects the most cost-effective process depending on your order quantity. However, you can of course change this at any time and adapt it to your individual requirements.

Would you like to configure a special shipping box without a lot of effort? At packaging-warehouse, we have made it our mission to make this process as simple as possible, yet flexible and with maximum control. We achieve this with our intelligent configurator. This makes it possible to quickly achieve a professional result without extensive prior knowledge in the field of packaging configuration.

For the exterior printing, you can choose between 4/0-colour Euroscale and 4/0-colour Euroscale + white. For the interior printing, you can choose between single-colour black or 4/0-colour Euroscale.

This is followed by two selection fields for the coating of your boxes. First, choose whether you would like a protective coating (matt or glossy) for your shipping box. Second, you can select a protective laminate if required. Here, you also have the choice between matt or glossy, but soft-touch laminate is also available.

Answer 1: We want to be the perfect partner for companies of all sizes – from large corporations to newly founded start-ups. For small businesses in particular, which may still be in the market entry phase with their product, large orders are not economical or often not feasible at all. That's why there are no minimum order quantities at packaging-warehouse. We can provide the perfect packaging solution for your business, starting from just one item.

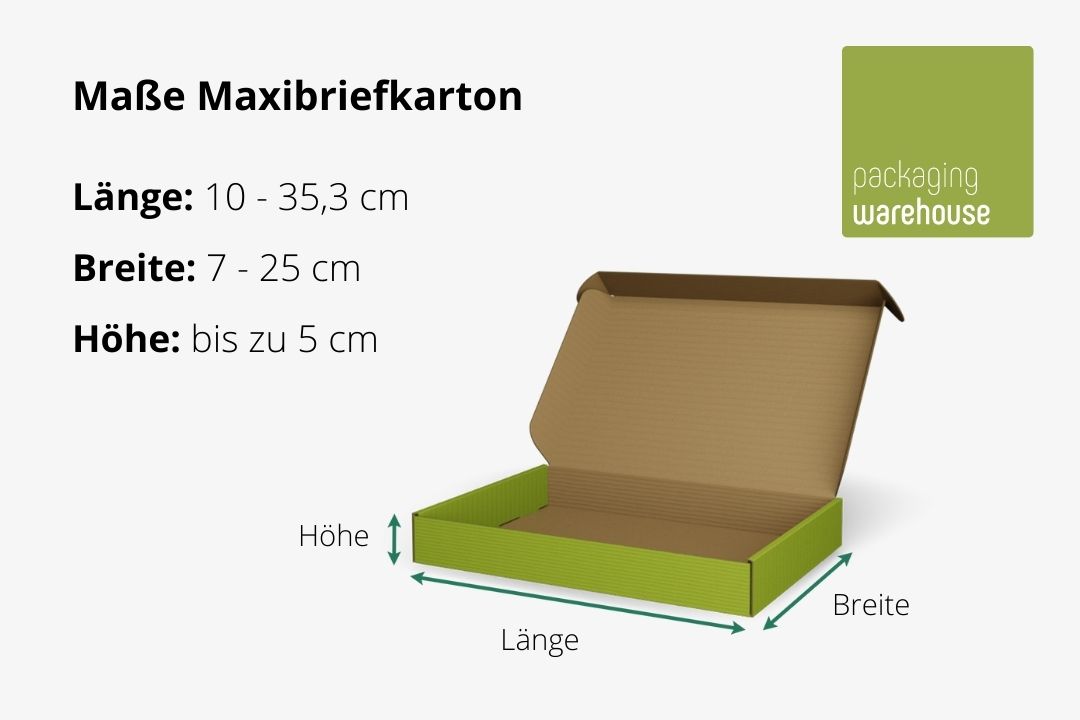

Answer 2: At packaging-warehouse, you can choose the format of your shipping box. We offer the following dimensions: length 60–700 mm, width 60–700 mm and height 15–250 mm. This makes it possible to configure a wide range of formats – from particularly small to particularly large cardboard boxes.

Do you have any further questions? No problem, our customer service team will be happy to help. All our employees are experts in the field of packaging and are on hand to offer you advice and assistance.